Thermoplastic CFRP for a better carbon footprint

Many composite laminate manufacturers are facing serious problems because their thermoset CFRP manufacturing is not sustainable. With COP27 and further climate change regulation looming, thermoplastic CFRP offers a greener alternative to thermoset CFRP for a wide range of industries.

COP27 Climate Change Conference 2022

Country leaders meet at COP 27 to decide on actions to advance collective climate goals agreed in the 2015 Paris Agreement on climate change. We should expect to see a higher level of commitments if global leaders are going to achieve the actions agreed in the Paris Agreement.

What does COP27 stand for?

- COP is the Conference of the Parties. Countries that were signatories to the original 1992 United Nations climate agreement.

- COP27 is the 27th UN climate change meeting. This year the annual meeting is being held in Egypt, at Sharm el-Sheikh

- This is the fifth time an African country has hosted the COP, recognizing that Africa is the continent most vulnerable to climate change effects.

- Governments attend the United Nations (UN) COP summit every year to make progress in limiting global temperature increases.

- A core aim of COP27 continues to be emissions reduction through renewable energy and fossil fuel reductions.

How will businesses respond to the climate change threat?

Businesses today are being forced to take action to respond to the necessity to anticipate legislation, and to take responsibility for reducing carbon footprints to meet corporate social responsibility goals. This has led to the Science Based Emissions Targets for Business and The UN Global Business Compact.

What eight actions can businesses take to reduce climate impacts?

- Manufacturing with recycled materials

- Making products easier to recycle

- Designing products for reuse

- Using less material in manufacturing processes

- Reducing waste from manufacturing

- Making products genuinely biodegradable

- Designing products that offer a greener alternative to an existing product

- Using renewable energy sources and reducing your carbon footprint

Thermoplastic CFRP For Sustainable Composite Laminates

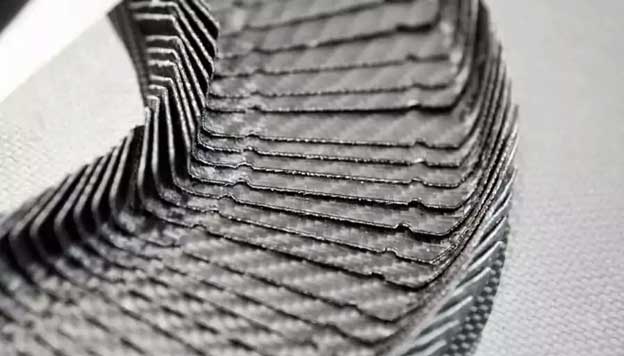

Thermoplastic Continuous Fiber Reinforced Plastic (CFRP) is a sustainable and recyclable alternative to composite laminate manufacture using Thermoset Epoxies. Thermoplastic CFRP is already delivering benefits in greener bicycle component manufacturing and recyclable carbon fiber composite laminates for footwear.

Today bicycle manufacturers have discovered new ways of using thermoplastic carbon composites in bicycle components, but thermoplastic CFRP is also an excellent, sustainable alternative to thermoset CFRP in sports protective equipment, aerospace, automotive, consumer electronics, and interior panels for buildings.

Thermoplastic CFRP can be as strong as thermoset alternatives, and capable of excellent finishes. Unlike thermoset CFRP, thermoplastic CFRP can be reheated and reused. Thermoplastic CFRP is also recyclable, offering a sustainable solution for CFRP manufacturing.

Why Our Customers Choose Complam CFRP

Complam is the provider of choice of bicycle components for many leading carbon fiber bike manufacturers because we deliver three reliable solutions that meet the sustainability needs of consumers and manufacturers.

- CFRP Closed-Loop Recycling

- CFRP Technology Leadership

- Green Manufacturing Solutions Using CFRP

CFRP closed-loop recycling

At Complam we offer a turnkey closed-loop manufacturing and recycling solution to our CFRP customers. We are able to recycle carbon fiber products and components as a regular part of our operations. Our recycling facility converts composite carbon fiber waste into resin-free carbon fiber and carbon felt, ready for reuse.

CFRTP technology leadership

Our carbon fiber reinforced thermoplastic (CFRTP) employs the newest and most advanced thermoplastic technologies to achieve remarkable reliability and outstanding strength to weight ratios for component manufacture.

Our leadership in CFRP innovation also enables us to make high strength, high quality CFRP using not only carbon fiber, but glass fiber or organic fibers to meet any engineering challenge our customers bring to us.

Green manufacturing solutions using CFRP

Complam sustainable composites can incorporate significant proportions of recycled resin, carbon fiber, glass fiber, or organic fibers in new products without affecting the excellent engineering and finish requirements our customers expect. We offer a green solution to the problem of manufacturing while reducing climate change impacts.

Contact Us

Contact us to find out how we can provide green and sustainable products that will satisfy your need for advanced composites in carbon fiber, glass fiber, or organic fibers. We offer high performance, durable, low carbon footprint CFRP with excellent visual appeal. Complam CFRP is also fully recyclable, demonstrating it is possible to have the benefits of CFRP and focus on sustainability.