Bio Fibers

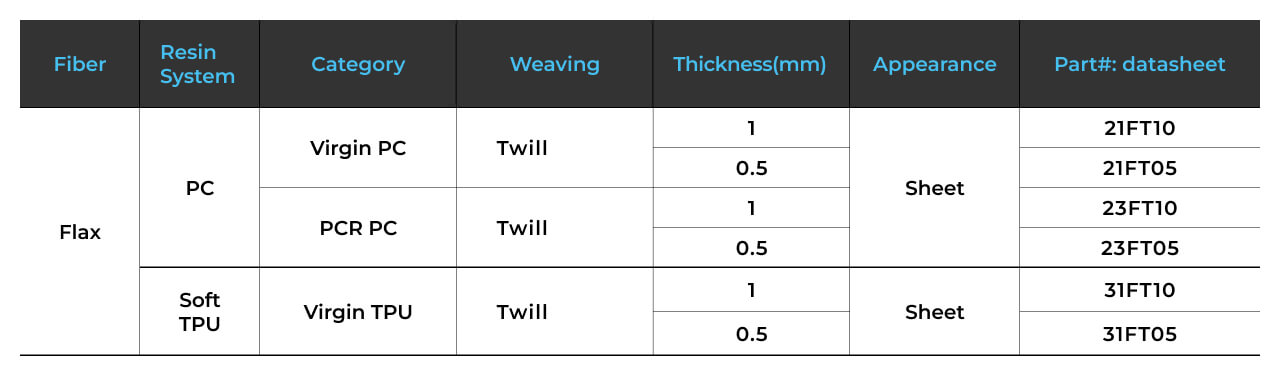

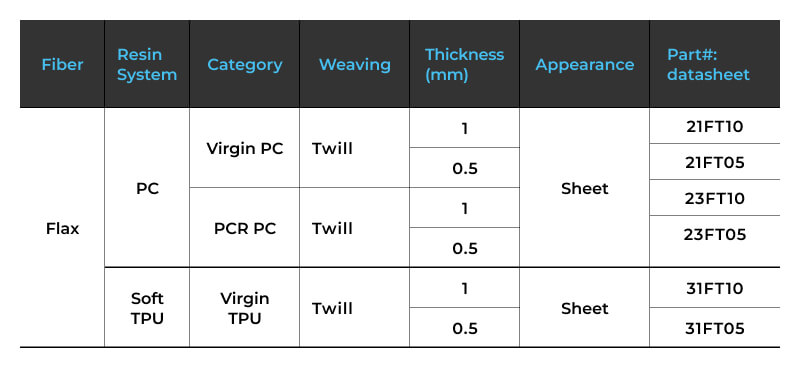

Our bio fiber solutions combined with our existing recycled carbon fiber and high performance resins deliver outstanding solutions to meet the latest challenges in composite materials applications.

At CompLam, we utilize a range of bio fibers that offer distinct qualities, and are chosen to meet the application requirements for each customer.

These bio fibers are integrated into our thermoplastic resin systems to enhance their functionality and versatility while also helping our customers meet their sustainability targets for using recycled and bio materials.

Most commonly used bio fibers include:

Embracing bio fibers and recycled carbon fiber components in our composite materials allows CompLam to reduce the environmental impact of your products significantly.

Our eco-friendly materials provide substantial marketing advantages. We enable brands to showcase their commitment to sustainability, potentially fostering deeper connections with environmentally-aware consumers.

Flame Retardant Materials

To cater to various industry demands, we also offer flame retardant laminates, crafted using our specially formulated PA6 and polycarbonate resins combined with our wide range or laminate materials.

At CompLam, we’re committed to delivering eco-conscious solutions that meet functional needs and exceed performance expectations, proving that sustainability, quality and value can coexist.

CompLam develops innovative and class-leading

material systems to meet the needs of industry.

Do you have any queries or comments about our website, our products or any of our services?

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. | |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |