The utility and sustainability of natural fiber composite laminates based on bio-fibers has caused a revolution in sustainable composite laminate manufacturing in multiple industries including automotive, aerospace and construction.

CompLam manufactures natural fiber composite laminates for the automotive, construction and sports industries. Bio-based natural fiber composite laminates are being adopted as the sustainable solution to the problem of manufacturing environmentally friendly composite laminate sheets with compound curves and intricate molded features.

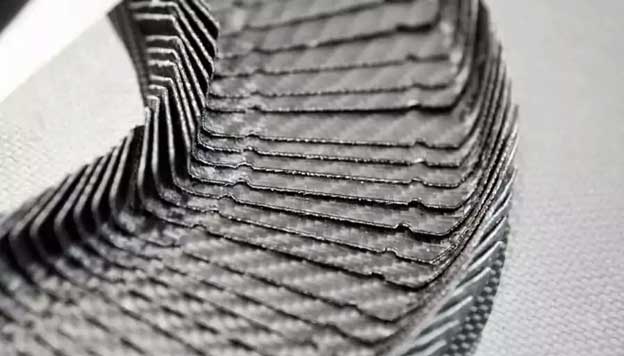

CompLam bio-fiber products are one line in our range of innovative products. Alongside our leadership in natural fiber composite laminates as a revolutionary alternative to synthetic fiber composite laminates, CompLam leads in carbon fiber composite laminate foot plates and new advances in bonding durable carbon fiber plates directly to fabrics.

What are the benefits of natural fiber composite laminates today?

With the growing awareness of the need to reduce energy consumption and carbon footprints in manufacturing industries, natural fibers have become the subject of intense research to develop more environmentally friendly alternatives to synthetic fibers and thermosetting epoxy resin technologies.

Innovations in processing, weaving and treatments of natural fiber fabrics to improve resin penetration and adhesion have made natural fiber composite laminates today perform as well as synthetic fiber laminates.

The combination of environmental sustainability and high performance is why natural fiber composite laminates are now found in automotive parts, construction materials and sports equipment, with increasing adoption in all industries that use fiber reinforced composites.

Why are flax fiber composite laminates preferred by the automotive & construction industries?

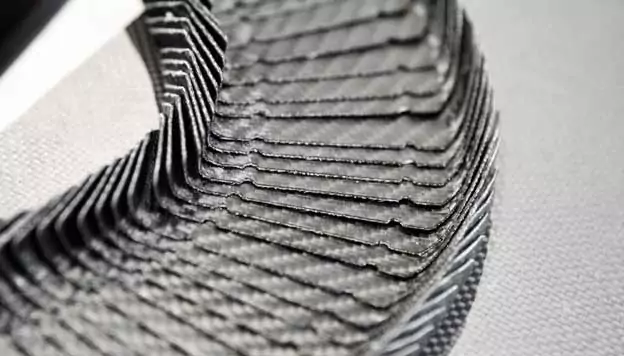

Sustainable manufacturing of complex laminate shapes continues to be a priority of automotive and aerospace companies looking to maintain leadership in competitive markets. Thermoplastic natural fiber composite laminates are an excellent way of achieving this combined requirement for engineering performance and sustainability.

Perhaps the best natural fiber for composite manufacturing is flax, which is lightweight with very strong, highly flexible fibers. This enables molding of complex shapes, and makes it an obvious choice for automotive panel manufacturing. Weight reduction through the use of flax fiber composite laminates also improves fuel efficiency and reduces emissions.

Flax-based bio-fiber composites are also very good thermal and acoustic insulators. These are advantages for the construction industry, which is working to manufacture greener buildings that combine energy saving features with a comfortable living environment.

Bio-based fibers are the new revolution in composite laminate manufacturing

The development of bio-based natural fiber composite laminates with excellent structural strength and engineering performance has enabled the new revolution in composite laminate manufacturing. Bio-based natural fiber composite laminates are well established in mainstream manufacturing industries, and the development of reliable thermoplastic resin technologies has accelerated the adoption of this highly sustainable product.

Laminating bio-based flax and other natural fibers with thermoplastic resins instead of thermoset resins creates products that can be easily molded but also recycled for maximum sustainability. Potential weight reduction and improved thermal and acoustic insulation properties make natural fiber laminates both more sustainable and technologically preferable to many thermoset synthetic fiber laminates.

Sustainable natural fiber composite laminates from CompLam

Our innovative natural fiber composite laminate technology enables us to produce thermoplastic flax fiber composite laminates which have the performance and visual appeal of synthetic laminates and the added benefit of increased sustainability.

When you combine our experienced designers and advanced technology with our state of the art manufacturing facilities and processes it is easy to see why we are the preferred supplier of high quality natural fiber composites to many globally recognized brands.

What are the benefits of CompLam thermoplastic flax fiber composites?

- Flax is a naturally sustainable material

- Flax fiber is extremely strong, for performance equal or better than many synthetic fibers

- Thermoplastic resins are recyclable, making thermoplastic flax fiber composites the greenest composite laminate technology available today

- Industry leading quality systems combine automated testing with human inspection and control for zero-defect manufacturing

CompLam’s thermoplastic laminates are the sustainable solution to consumer requirements for high performance products that are environmentally friendly. Contact us to discover our range of bio-fiber based composite laminates and discuss how we can satisfy your needs for greener products that enhance your brand.