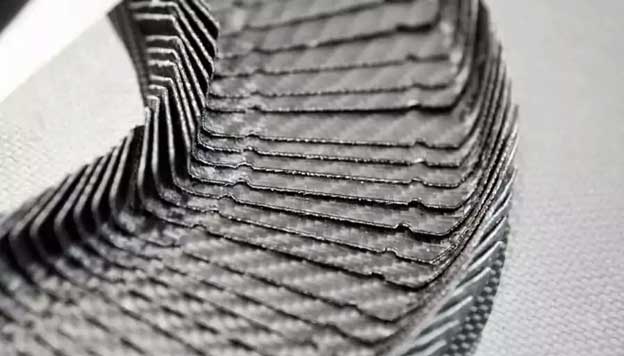

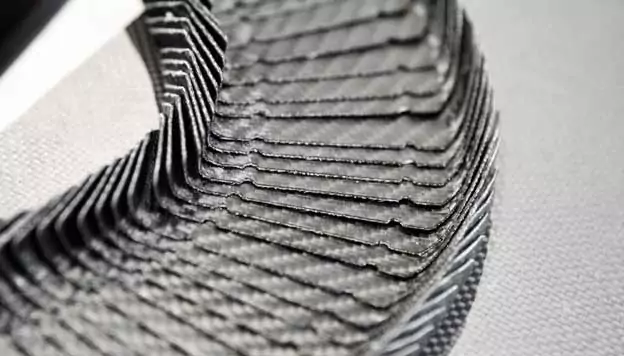

Bio-fiber based composite laminates are a sustainable solution for composite panels in various industries, including but not limited to automotive and construction applications

Are flax fiber composite laminates the best bio-fiber substitute for synthetic fibers?

Among bio-fibers that are suitable for composite laminate manufacturing, flax fiber is perhaps the best direct replacement for most synthetic fibers. Composite laminate research has focused on flax fiber as the strongest natural plant fiber. This enables flax fiber composite laminates to meet engineering requirements for high flexural strength and modulus of elasticity.

How easy is it to switch to flax fiber composite laminates?

Manufacturing industries seeking more sustainable engineering solutions for composite laminates can find it difficult to switch from less sustainable synthetic fibers and resins to bio-fiber and recycled alternatives. Flax fiber, hemp, jute, and other bio-based reinforcements have different physical and chemical characteristics to glass fiber and carbon.

If you are looking for 100% bio-based laminates you should look for composite laminate manufacturers with the experience to help you develop workable solutions. It isn’t simply a matter of substituting bio-fibers for glass or carbon fiber. Developing bio-fiber composite laminates requires research and testing to achieve reliable, durable and visually appealing results.

What makes flax fiber composite laminates a sustainable solution?

When you manufacture composite laminates from flax fiber using thermoplastic resin you are significantly increasing the environmental gains compared to thermoset laminate fabrication. Thermoplastic flax fiber composite panels can be manufactured with recycled resin, including PA11 nylon. The resulting thermoplastic panels can be recycled much more easily than thermoset, epoxy-based, composites, adding to the circular economy.

What are 6 benefits of flax fiber thermoplastic composite laminates?

- Stronger than standard plastic components

- Bio-based sustainable sourcing of materials

- Natural appearance appeals to environmentally conscious consumers

- Requires less energy than petroleum-based materials

- Flax fiber is 100% biodegradable

- High impact resistance with excellent flexural strength and modulus

Natural fibers require less energy in manufacturing, which reduces greenhouse gas emissions from the production process. The reduction in the use of fossil fuels and petroleum based raw materials along with the use of recycled resins and increased recyclability makes bio-fiber composite laminates a greener, environmentally friendly technology compared to glass fiber, carbon and epoxy based laminates.

Are there any barriers to flax fiber composite laminate manufacturing

Research into bio-based laminates demonstrates that thermoforming of flax fiber composites need to be carefully managed under temperature controlled conditions to avoid overheating the laminate, which reduces performance by weakening the structure and reducing elasticity. Flax fiber must not be heated over 180C and retains moisture that needs to be removed before processing.

Use of low temperature resins including TPU and PP makes it possible to thermoform without damaging the flax fiber, but successfully manufacturing flax fiber composite laminates is more demanding than standard composite technologies, and requires experience and technical competencies in designing and testing new products.

How does CompLam overcome the potential barriers to flax fiber laminate manufacturing?

- Using resins that keep the thermoforming temperature below the flax fiber limit of 180°C

- Extensive testing history of lamination parameters for optimum results

- Experience to offer valuable recommendations for post production

- Comprehensive quality management and in-house control of the entire process

Why is CompLam your partner of choice for flax fiber composite laminate manufacturing?

Thermoplastic resin formulations for flax fiber composite laminates need to be carefully tested and undergo quality control assessment to ensure they meet design standards for strength and durability. At CompLam we have established robust quality control systems that combine human and automated inspection regimes to ensure our bio-fiber composite laminates meet or exceed the requirements of our customers.

We have well established natural fiber thermoforming experience with our strategic partners, using thermoplastic recycled resins and bio-fiber. Our success in achieving stable, high performance laminates is demonstrated by their adoption in demanding applications including high performance bicycle components.

Our capabilities for offering a single source for recycled resins and both synthetic and bio-fibers mean we can offer our customers rapid prototyping and production ready designs extremely quickly without the added risks of outsourcing to less experienced suppliers. Contact us to discover how CompLam thermoplastic flax fiber composites can boost the sustainability of your brand without compromising on performance.