Meeting Sustainability Challenges For Global Brands With Our Carbon Fiber Recycling Solution

- Rapidly increasing market demand for CFRP products

- Increasing regulatory pressure for recycling Especially in EU

- Corporate Sustainability targets to maintain brand image

- Consumer pressure, especially in sports & leisure

The increasing demand for high quality CFRP products comes at a time of increasing pressure from regulators to achieve better recycling targets. There are also significant corporate benefits in demonstrating to consumers that manufacturers are achieving sustainability targets because consumers make choices based on environmental impact.

The CompLam Carbon Fiber Recycling Solution

- Provides a channel for manufacturers’ carbon fiber waste to be recycled

- Reclaims fibers and incorporates with CompLam resins in new CFRP

- Provides a sustainability solution for brands

CompLam works with footwear and bicycle brands to help them meet targets for post consumer recycling without compromising on the demand for high quality, attractive products. Brands send us carbon fiber scrap and end user waste for recycling.

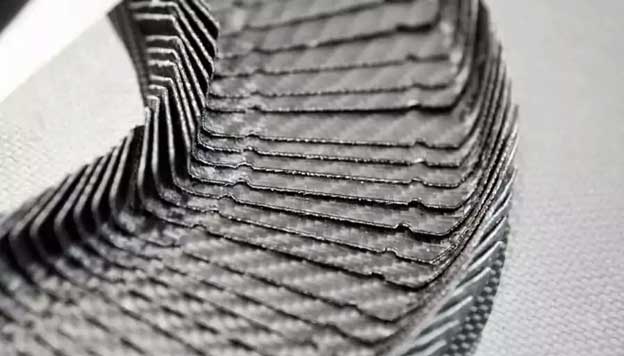

In our partnership with bicycle and footwear brands, we recycle carbon fiber scrap into reusable carbon fiber pellets and felt. We recycle both manufacturing scrap and end user waste to close the loop between waste management and new product manufacture.

Advantages of Our Carbon Fiber Recycling Process

- Adds value to scrap from end users & manufacturers

- Integrates with brand sustainability initiatives

- CompLam active tracking delivers carbon footprint offset data

Recycling with CompLam has many benefits. Cost savings can be made by using manufacturing and end user scrap to make new products because it offsets the cost of disposal and reduces the volume of new material required. We provide a turnkey solution to enhancing brand sustainability messages, including the data required to calculate your carbon offset.

CompLam Reclamation Technology Advantages

- Can recycle both thermoplastic and thermoset parts

- Recycling solution already in live production now

- Most efficient process for thermoset – Microwave Pyrolysis

- Most efficient solution for carbon footprint reduction

The CompLam process recycles thermoset and thermoplastic parts using highly efficient technology to produce high quality fibers and reduce carbon footprint. Because our recycling system is in live production we can work with you to recycle and reuse your thermoplastic and thermoset waste without delay.

Recycled Material Performance

- Pure recycled fibers are resin free

- Can be incorporated into virgin fiber laminates

- Use of long fiber thermoplastics supports GRS targets

Our manufacturing process uses the latest innovations for collation and size reduction to ensure uniform, resin-free, recycled fibers that are ready for reuse in new products. The high quality and purity of our recycled fibers means they can be layered with virgin fiber without compromising finish and appearance.

Committed To Global Recycling Standards

The increasing emphasis on environmental protection standards means that consumers are looking for products that support Global Recycling Standard targets. Our production process is scheduled for full GRS registration in July 2022, and enables you to demonstrate your commitment to green manufacturing.